大庆消防箱箱体生产线定做

浏览次数:187次

- 产品规格:

- 发货地:山东省潍坊潍城区

关键词

大庆消防箱箱体生产线定做

详细说明

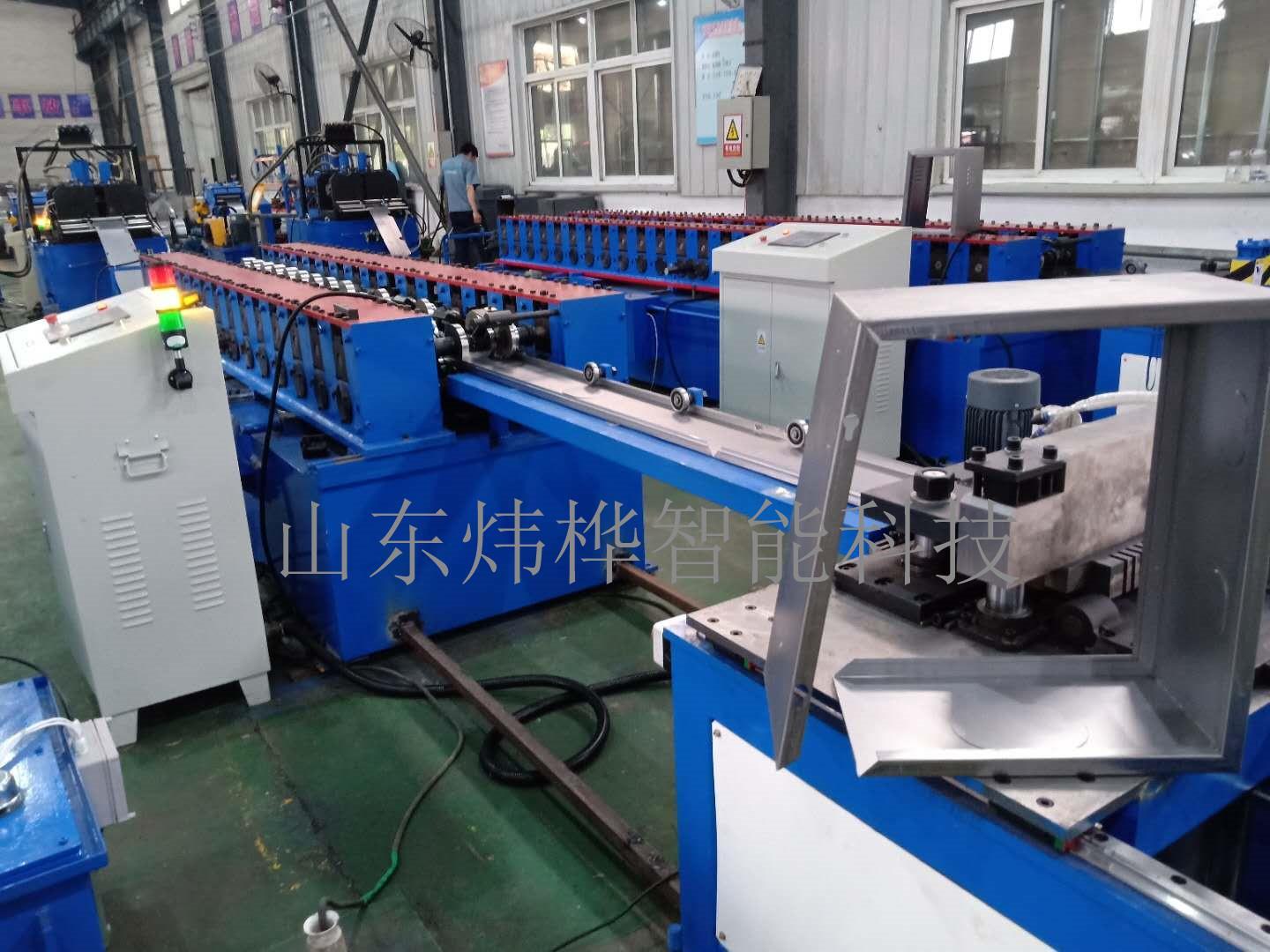

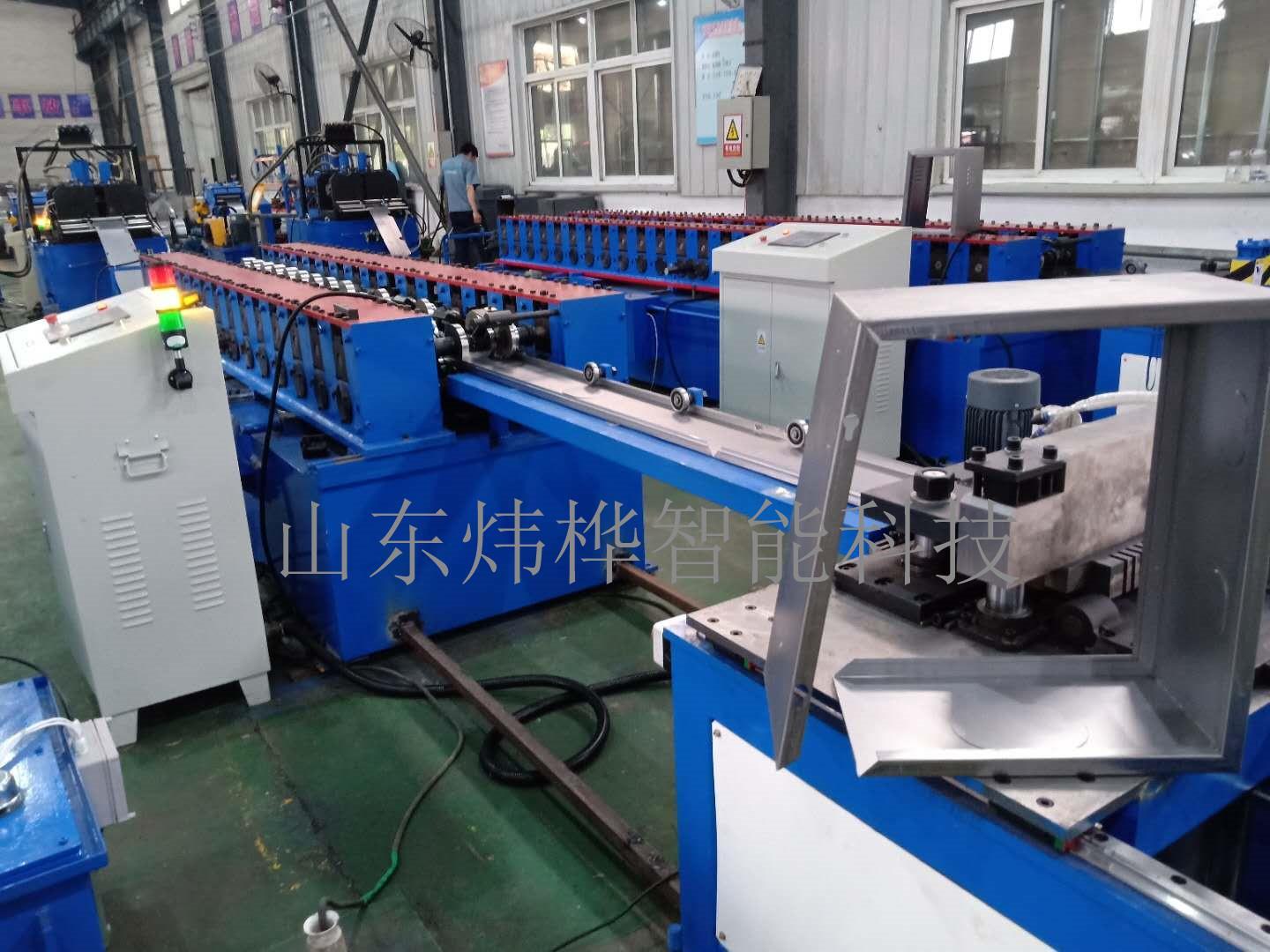

消防箱作为配备水、水袋等配件的消防行业的必备产品,近年来随着经济的高速发展和百姓的安全意识的增强,使用量也大幅提高,炜桦研发的这套优质消防箱成型设备具备高效率高品质高精度的智能化连续生产特点,通过将钢卷开卷后进行一系列的校平送料、冲孔切角、滚压成型、数控折弯、切断之后就能出来整个箱子的四边框体,敲落孔也可以在线上直接冲出,想要调节规格的话可以配置手动摇轮调节和电动调节,都是没有问题的,技术人员设计的时候已经充分考虑到了客户的方便性,以人为本。质保期为12个月,从到我们厂验收合格,拉回公司之日起,除易损耗的件外,其余免费保修,终身提供技术服务,设备质量与售后服务双线赢得客户信赖。

1.放料机:用于存入放卷料并给成形部分提供板料,5吨电动放料机液压张紧。

“炜桦冷弯”我公司是山东科技职业学院校企,注册资金1015万,拥有强大的设计研发能力,结合国际先进的设计理念,自主设计研发提供的基业电气箱生产设备、电表箱成型设备、威图柜外壳一次成型生产线为定制设备,弱电箱生产设备、动力箱壳体成型设备(自动送料、冲孔、折弯、焊接、成型、一次完成)可根据客户的不同需求,集成生产所需的众多工艺,自动送料、冲孔、成型、折弯、焊接等等。这些都将为生产能力和产品品质带来极大提高。炜桦冷弯自主研发生产威图柜骨架生产设备、威图柜外壳成型设备、综合布线箱全自动成型设备、基业配电箱生产设备,不锈钢电气柜成型设备、弱电箱壳体生产线、弱电布线箱生产设备。多媒体集线箱外壳自动折弯成型设备(自动送料、冲孔、折弯、焊接、成型、一次完成)。

"Weibi Cold Bending" Company is a school enterprise of Shandong Vocational College of Science and Technology, with registered capital of 10.15 million. It has strong design and development ability. Combining with the advanced international design concept, we independently design and provide basic electrical box production equipment, watt-hour meter box forming equipment, Weitu cabinet shell forming production line as customized equipment, weak electric box production equipment, power box shell forming equipment (self-made). Dynamic feeding, punching, bending, welding, forming, one-time completion) according to the different needs of customers, integrated production needs of many processes, automatic feeding, punching, forming, bending, welding and so on. All of these will greatly improve the production capacity and product quality. Weibi cold bending independent research and development and production of Weitu cabinet skeleton production equipment, Weitu cabinet shell forming equipment, integrated cabinet automatic forming equipment, basic distribution box production equipment, stainless steel electrical cabinet forming equipment, weak cabinet shell production line, weak cabinet production equipment. Multimedia hubs shell automatic bending forming equipment (automatic feeding, punching, bending, welding, forming, one-time completion).

a. 电源 : 380V/50HZ/3PH

Power supply: 380V/50HZ/3PH

b. 装机容量: 约31Kw

B. Installation capacity: about 31Kw

c. 成型速度: 0-13m/min

C. Molding speed: 0-13m/min

d. 剪切方式: 伺服前剪

D. Cutting mode: Servo front shear

e. 驱动电机: 开卷机马达 4KW

E. Driving motor: uncoiler motor 4KW

调平机马达 2.2KW

Leveling Machine Motor 2.2KW

液压冲孔切断及液压张紧马达(两台) 11KW+7.5KW

Hydraulic Punch Cutting and Hydraulic Tension Motor (Two) 11KW+7.5KW

成型主机马达 5.5KW

Molding Host Motor 5.5KW

伺服电机马达 2KW

Servomotor motor 2KW

f. 占地面积(约):长24m×宽3m (主机规格7mX1.7m)

F. Coverage (approximate): 24m long by 3M wide (host specification 7mX1.7m)

g. 生产线方向:由左至右(在操作台面向机组)。

G. Direction of production line: from left to right (facing unit at operating table).

h. 设备颜色:(客户选择)

H. Equipment color: (customer selection)

i. 机组设备设计可满足12小时连续生产

I. Unit equipment design can meet 12 hours continuous production

j. 运行环境:

J. Operating environment:

1:电源电压:380V±10%/三相四线,频率:50HZ 总功率:约31KW

1: Power supply voltage: 380V + 10%/three-phase four-wire, frequency: 50HZ total power: about 31KW

2: 环境温度:0-40℃,相对湿度:60-95%RH。

2: ambient temperature: 0-40 C, relative humidity: 60-95% RH.

二.设备组成

II. Equipment Composition

1. 动力开料机及液压张紧装置

1. Power feeder and hydraulic tensioner

2. 动力调平机

2. Power Leveling Machine

3. 伺服冲孔切断装置

3. Servo Punch Cutting Device

4. 输送台

4. conveyor

5. 成型主机

5. Forming Host

6. 液压折边机

6. Hydraulic hemming machine

7. 液压系统

7. Hydraulic system

8. 电气设备

8. Electrical equipment

9. 成品托料辊

9. finished product support roll

山东炜桦智能科技有限公司公司(前身是潍坊炜桦冷弯机械制造有限公司),经过多年的生产经验、市场反馈及市场分析,设计、研发及生产了新型消火栓箱冷弯生产设备,设备及冲压、冷弯成型、切断折弯与一体,设备生产速度快,每小时可生产100-120个箱体左右,成型后缝隙小且美观。

m.weifangweihua.b2b168.com

1.放料机:用于存入放卷料并给成形部分提供板料,5吨电动放料机液压张紧。

“炜桦冷弯”我公司是山东科技职业学院校企,注册资金1015万,拥有强大的设计研发能力,结合国际先进的设计理念,自主设计研发提供的基业电气箱生产设备、电表箱成型设备、威图柜外壳一次成型生产线为定制设备,弱电箱生产设备、动力箱壳体成型设备(自动送料、冲孔、折弯、焊接、成型、一次完成)可根据客户的不同需求,集成生产所需的众多工艺,自动送料、冲孔、成型、折弯、焊接等等。这些都将为生产能力和产品品质带来极大提高。炜桦冷弯自主研发生产威图柜骨架生产设备、威图柜外壳成型设备、综合布线箱全自动成型设备、基业配电箱生产设备,不锈钢电气柜成型设备、弱电箱壳体生产线、弱电布线箱生产设备。多媒体集线箱外壳自动折弯成型设备(自动送料、冲孔、折弯、焊接、成型、一次完成)。

"Weibi Cold Bending" Company is a school enterprise of Shandong Vocational College of Science and Technology, with registered capital of 10.15 million. It has strong design and development ability. Combining with the advanced international design concept, we independently design and provide basic electrical box production equipment, watt-hour meter box forming equipment, Weitu cabinet shell forming production line as customized equipment, weak electric box production equipment, power box shell forming equipment (self-made). Dynamic feeding, punching, bending, welding, forming, one-time completion) according to the different needs of customers, integrated production needs of many processes, automatic feeding, punching, forming, bending, welding and so on. All of these will greatly improve the production capacity and product quality. Weibi cold bending independent research and development and production of Weitu cabinet skeleton production equipment, Weitu cabinet shell forming equipment, integrated cabinet automatic forming equipment, basic distribution box production equipment, stainless steel electrical cabinet forming equipment, weak cabinet shell production line, weak cabinet production equipment. Multimedia hubs shell automatic bending forming equipment (automatic feeding, punching, bending, welding, forming, one-time completion).

a. 电源 : 380V/50HZ/3PH

Power supply: 380V/50HZ/3PH

b. 装机容量: 约31Kw

B. Installation capacity: about 31Kw

c. 成型速度: 0-13m/min

C. Molding speed: 0-13m/min

d. 剪切方式: 伺服前剪

D. Cutting mode: Servo front shear

e. 驱动电机: 开卷机马达 4KW

E. Driving motor: uncoiler motor 4KW

调平机马达 2.2KW

Leveling Machine Motor 2.2KW

液压冲孔切断及液压张紧马达(两台) 11KW+7.5KW

Hydraulic Punch Cutting and Hydraulic Tension Motor (Two) 11KW+7.5KW

成型主机马达 5.5KW

Molding Host Motor 5.5KW

伺服电机马达 2KW

Servomotor motor 2KW

f. 占地面积(约):长24m×宽3m (主机规格7mX1.7m)

F. Coverage (approximate): 24m long by 3M wide (host specification 7mX1.7m)

g. 生产线方向:由左至右(在操作台面向机组)。

G. Direction of production line: from left to right (facing unit at operating table).

h. 设备颜色:(客户选择)

H. Equipment color: (customer selection)

i. 机组设备设计可满足12小时连续生产

I. Unit equipment design can meet 12 hours continuous production

j. 运行环境:

J. Operating environment:

1:电源电压:380V±10%/三相四线,频率:50HZ 总功率:约31KW

1: Power supply voltage: 380V + 10%/three-phase four-wire, frequency: 50HZ total power: about 31KW

2: 环境温度:0-40℃,相对湿度:60-95%RH。

2: ambient temperature: 0-40 C, relative humidity: 60-95% RH.

二.设备组成

II. Equipment Composition

1. 动力开料机及液压张紧装置

1. Power feeder and hydraulic tensioner

2. 动力调平机

2. Power Leveling Machine

3. 伺服冲孔切断装置

3. Servo Punch Cutting Device

4. 输送台

4. conveyor

5. 成型主机

5. Forming Host

6. 液压折边机

6. Hydraulic hemming machine

7. 液压系统

7. Hydraulic system

8. 电气设备

8. Electrical equipment

9. 成品托料辊

9. finished product support roll

山东炜桦智能科技有限公司公司(前身是潍坊炜桦冷弯机械制造有限公司),经过多年的生产经验、市场反馈及市场分析,设计、研发及生产了新型消火栓箱冷弯生产设备,设备及冲压、冷弯成型、切断折弯与一体,设备生产速度快,每小时可生产100-120个箱体左右,成型后缝隙小且美观。

m.weifangweihua.b2b168.com