柳州消防箱箱体生产线厂

浏览次数:135次

- 产品规格:

- 发货地:山东省潍坊潍城区望留街道

关键词

柳州消防箱箱体生产线厂

详细说明

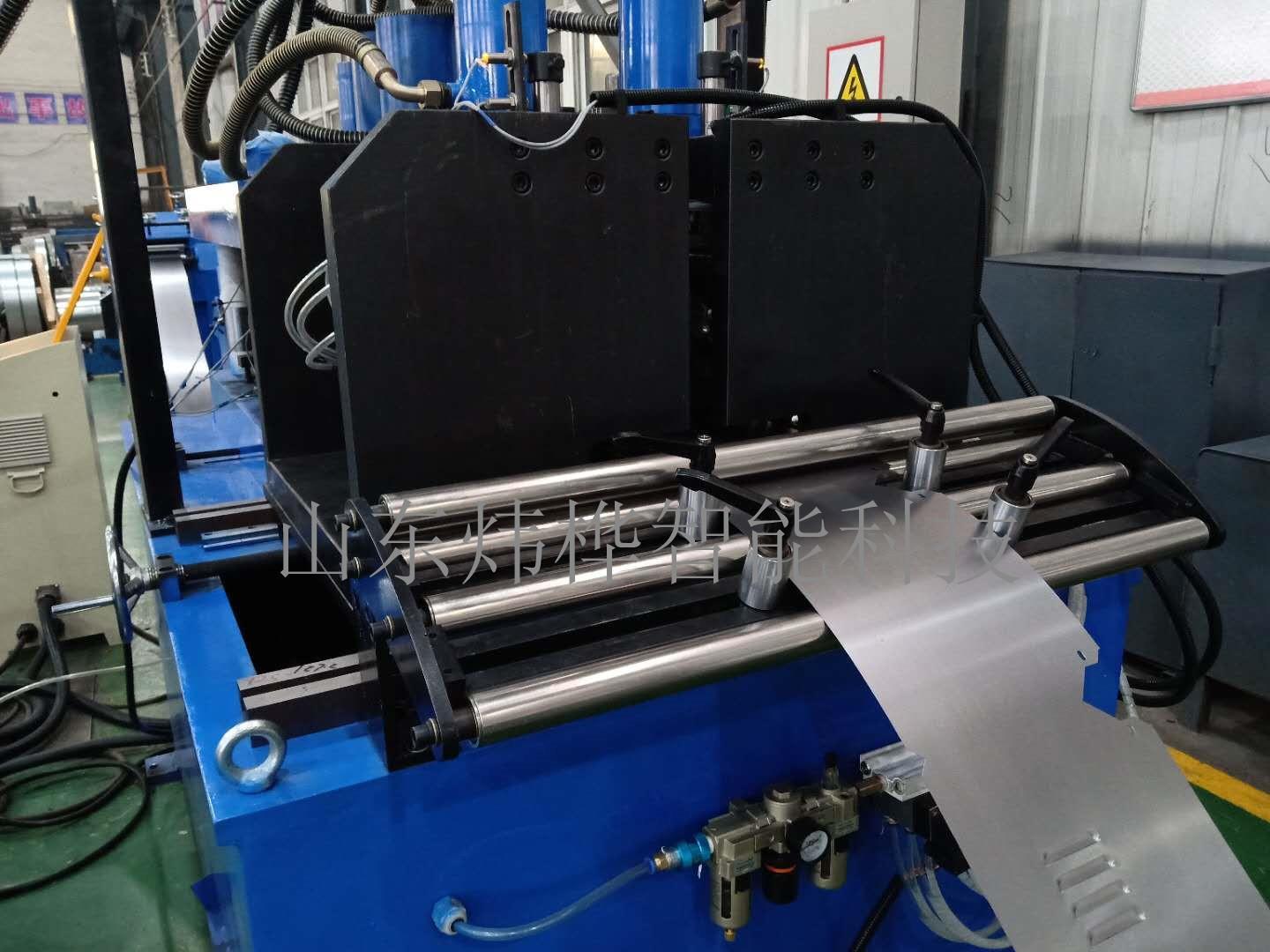

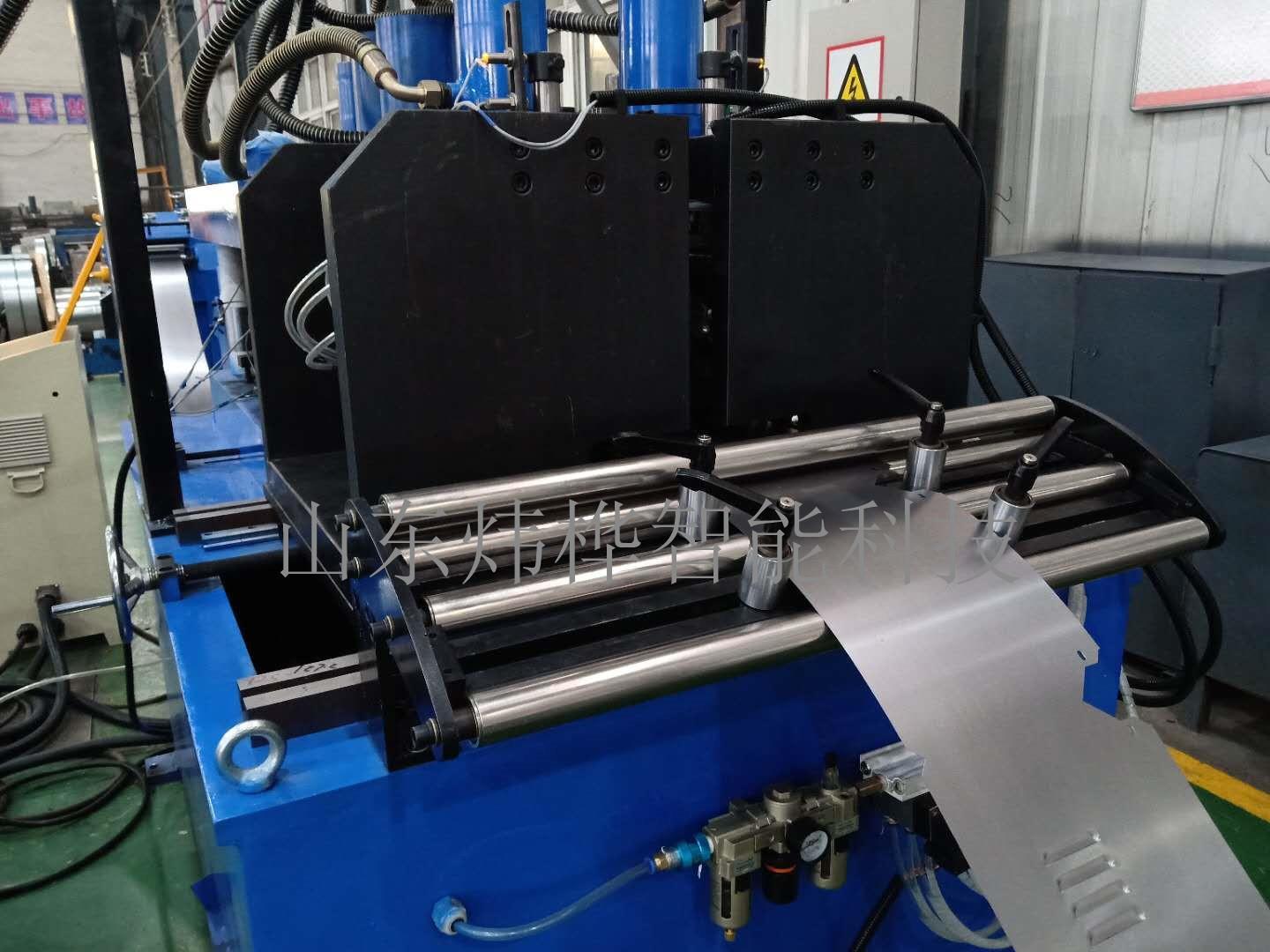

配电箱箱体冷弯成型设备的核心部件是轧辊模具,潍坊炜桦冷弯机械有限公司在轧辊制造方面,先由技术部进行专业的设计,经过严格审核后流转到生产部加工,我们采用的材料材质都是非常优质的,为保障轧辊的 使用寿命,我们有着严格有序的加工流程,虽然繁琐一些,但是能够让客户用着放心舒心,一切也是值得的。具体的轧辊加工流程这里不便详细说明,您有兴趣的话可以找我们了解一下。

The core component of cold bending forming equipment for distribution box body is roll mould. Weifang Weihua Cold Bending Machinery Co., Ltd. specializes in roll manufacturing. After strict examination, it is transferred to the production department for processing. The materials we adopt are of very high quality. In order to ensure the service life of rolls, we have a strict and orderly processing process, although complicated. It's trivial, but it's worth it to make customers feel at ease with it. Specific roll processing process here is not convenient to elaborate, if you are interested, you can find out about us.

配电箱自动冷弯成型生产线为定制化设备,可根据客户的不同需求,集成生产所需的众多工艺,如自动换料机、切割和冲压系统,以及复杂的焊接、铆接、折弯、搬运和包装等系统。这些都将为提高生产能力带来巨大的附加值。其生产的冷弯成型生产线设备:轧制材料的材质包括冷轧钢带、热轧钢带、酸洗板(钢带)、彩钢板(钢带)、镀锌钢带和不锈钢带等;高精度成型机专业制造能处理0.2mm—12mm厚金属板材;生产出来的型材尺寸精度可以控制在0.05毫米以内,这在国内具有行业领先地位。

The automatic cold bending production line for distribution boxes is customized equipment. It can integrate many processes required for production according to different needs of customers, such as automatic feeder, cutting and stamping system, and complex welding, riveting, bending, handling and packaging systems. All of these will bring huge added value to the improvement of production capacity. The cold bending production line equipment: the material of rolling material includes cold rolled steel strip, hot rolled steel strip, pickling plate (steel strip), coloured steel strip (steel strip), galvanized steel strip and stainless steel strip, etc. The high precision forming machine specializes in manufacturing thick metal sheet which can handle 0.2mm-12mm; the dimension precision of the produced profile can be controlled within 0.05mm, which is the leading industry in China. Position.

钢带厚度:1.0~2.0 mm

Strip thickness: 1.0-2.0 mm

钢带宽度:≤500mm,

Width of steel band: <500 mm,

轧辊材质:GCr15 淬火HRC58°-62°

Roll Material: GCr15 Quenched HRC58 Degree-62 Degree

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

总电机功率:27kw

Total motor power: 27 kw

液压系统功率:3kw

Hydraulic system power: 3kw

承重钢带:3吨

Load-bearing steel strip: 3 tons

主要轧辊数量:18

Number of main rolls: 18

切断尺寸公差:≤ ±0.5mm(长≤3000mm)

Cut-off dimension tolerance: <0.5mm (length <3000mm)

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

气源:0.5m³/Min;压力为0.7MPa

Gas source: 0.5m_/Min; pressure 0.7MPa

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

潍坊炜桦冷弯机械制造有限公司始建于2004年,公司致力于“钣金成型自动化设备”、“金属成型自动化生产线”的研发、设计、生产、销售。我们以“友好守信、精诚协作、品质兼优、服务至上”为经营理念,通过先进的技术,优质的设备,优惠的价格,竭诚为国内外新老客户提供服务。

消火栓箱自动生产线技术参数:

开卷:被动上料架

放料架承重:5T

机架:采用方管焊接

中板厚:18mm

成型机导向进料架形式:侧向滚轮式

成型机形式:墙板式链传动

传动方式:齿轮箱

成型机线速度:7-10m/min

成型机道数:七辊校平16道成型。

轧辊材料:轴承钢

轧辊热处理:HRC58°-60

液压站电机:5.5KW

液压站油泵:齿轮泵

切断方式:无极切断,无需更换切刀磨具

轧制厚度:1.0-3.0mm

m.weifangweihua.b2b168.com

The core component of cold bending forming equipment for distribution box body is roll mould. Weifang Weihua Cold Bending Machinery Co., Ltd. specializes in roll manufacturing. After strict examination, it is transferred to the production department for processing. The materials we adopt are of very high quality. In order to ensure the service life of rolls, we have a strict and orderly processing process, although complicated. It's trivial, but it's worth it to make customers feel at ease with it. Specific roll processing process here is not convenient to elaborate, if you are interested, you can find out about us.

配电箱自动冷弯成型生产线为定制化设备,可根据客户的不同需求,集成生产所需的众多工艺,如自动换料机、切割和冲压系统,以及复杂的焊接、铆接、折弯、搬运和包装等系统。这些都将为提高生产能力带来巨大的附加值。其生产的冷弯成型生产线设备:轧制材料的材质包括冷轧钢带、热轧钢带、酸洗板(钢带)、彩钢板(钢带)、镀锌钢带和不锈钢带等;高精度成型机专业制造能处理0.2mm—12mm厚金属板材;生产出来的型材尺寸精度可以控制在0.05毫米以内,这在国内具有行业领先地位。

The automatic cold bending production line for distribution boxes is customized equipment. It can integrate many processes required for production according to different needs of customers, such as automatic feeder, cutting and stamping system, and complex welding, riveting, bending, handling and packaging systems. All of these will bring huge added value to the improvement of production capacity. The cold bending production line equipment: the material of rolling material includes cold rolled steel strip, hot rolled steel strip, pickling plate (steel strip), coloured steel strip (steel strip), galvanized steel strip and stainless steel strip, etc. The high precision forming machine specializes in manufacturing thick metal sheet which can handle 0.2mm-12mm; the dimension precision of the produced profile can be controlled within 0.05mm, which is the leading industry in China. Position.

钢带厚度:1.0~2.0 mm

Strip thickness: 1.0-2.0 mm

钢带宽度:≤500mm,

Width of steel band: <500 mm,

轧辊材质:GCr15 淬火HRC58°-62°

Roll Material: GCr15 Quenched HRC58 Degree-62 Degree

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

总电机功率:27kw

Total motor power: 27 kw

液压系统功率:3kw

Hydraulic system power: 3kw

承重钢带:3吨

Load-bearing steel strip: 3 tons

主要轧辊数量:18

Number of main rolls: 18

切断尺寸公差:≤ ±0.5mm(长≤3000mm)

Cut-off dimension tolerance: <0.5mm (length <3000mm)

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

气源:0.5m³/Min;压力为0.7MPa

Gas source: 0.5m_/Min; pressure 0.7MPa

2.整平机:9辊精密整平(上4下5),2.2KW电动送料,用于卷料平直并消除材料应力。

潍坊炜桦冷弯机械制造有限公司始建于2004年,公司致力于“钣金成型自动化设备”、“金属成型自动化生产线”的研发、设计、生产、销售。我们以“友好守信、精诚协作、品质兼优、服务至上”为经营理念,通过先进的技术,优质的设备,优惠的价格,竭诚为国内外新老客户提供服务。

消火栓箱自动生产线技术参数:

开卷:被动上料架

放料架承重:5T

机架:采用方管焊接

中板厚:18mm

成型机导向进料架形式:侧向滚轮式

成型机形式:墙板式链传动

传动方式:齿轮箱

成型机线速度:7-10m/min

成型机道数:七辊校平16道成型。

轧辊材料:轴承钢

轧辊热处理:HRC58°-60

液压站电机:5.5KW

液压站油泵:齿轮泵

切断方式:无极切断,无需更换切刀磨具

轧制厚度:1.0-3.0mm

m.weifangweihua.b2b168.com