吉林配电箱箱体设备定制

浏览次数:35次

- 产品规格:

- 发货地:山东省潍坊潍城区望留街道

关键词

吉林配电箱箱体设备定制

详细说明

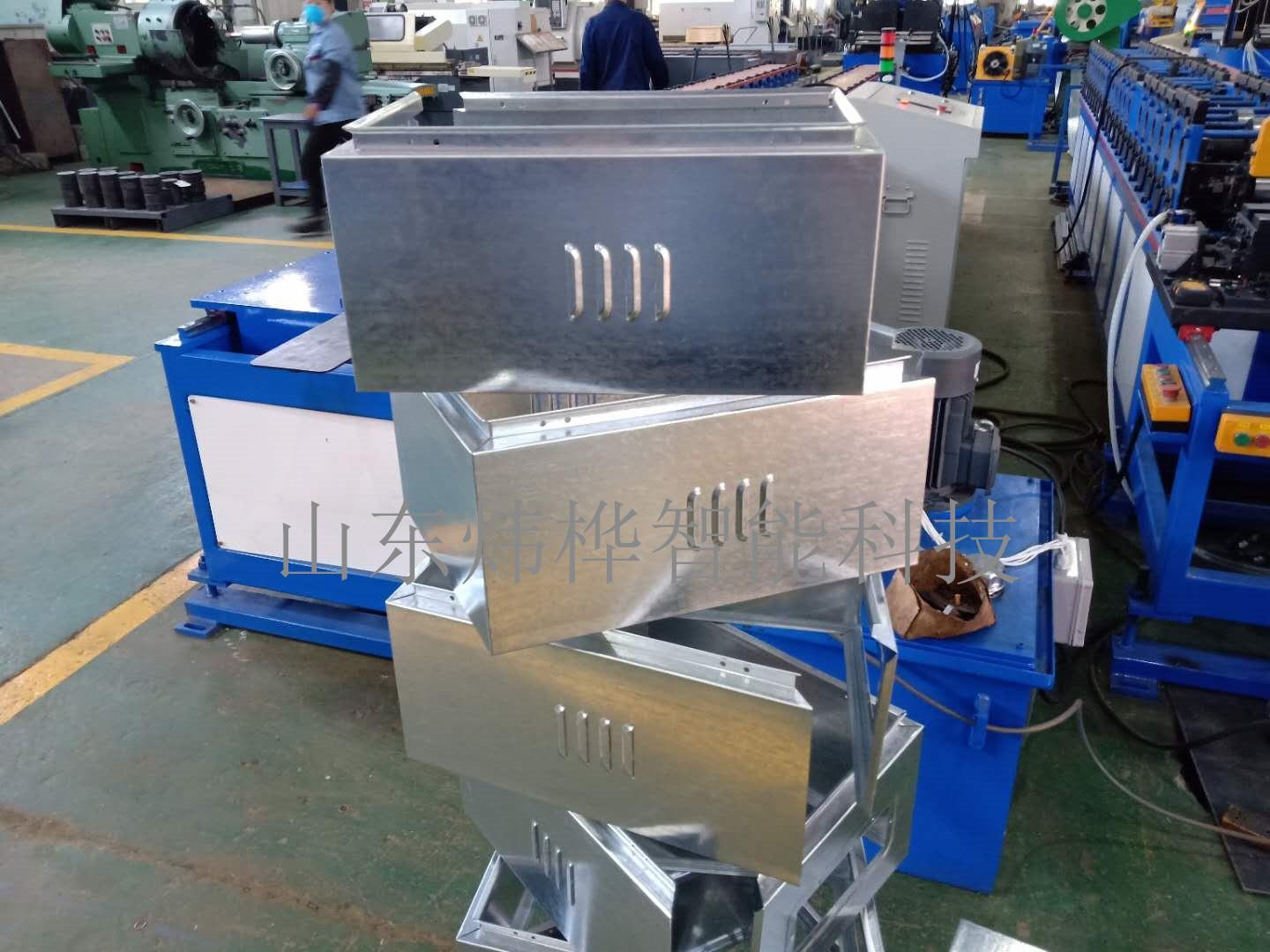

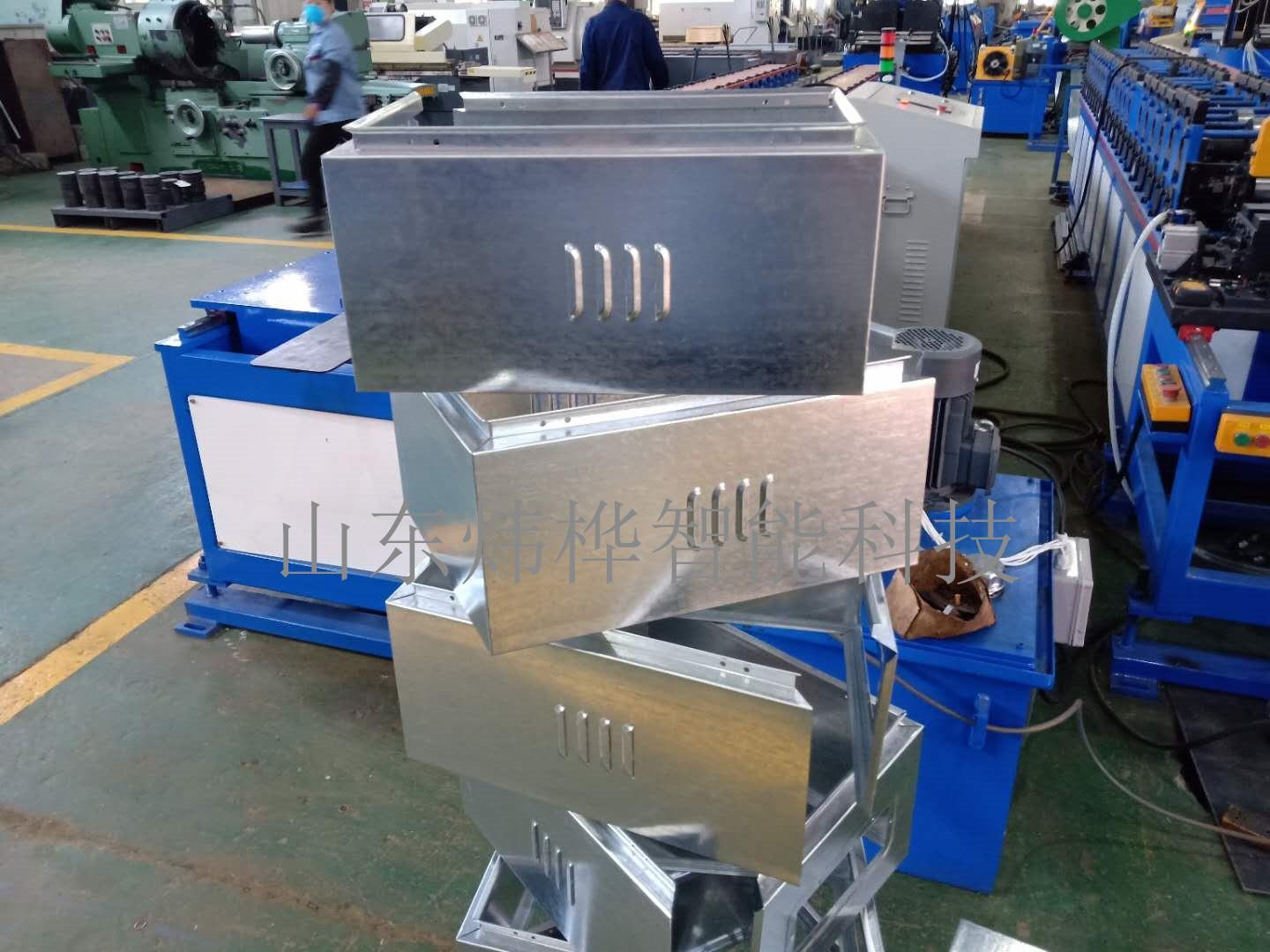

明装电气箱外壳体全自动生产线、中置箱自动生产线一个人即可快速生产。即节省了人工,又提高了生产效率,同时还提升了产品品质。

The automatic production line of open-packed electric box shell and the automatic production line of middle-packed electric box can be produced quickly by one person. It not only saves the labor, but also improves the production efficiency, and at the same time improves the product quality.

我公司是山东科技职业学院校企,注册资金1015万,拥有强大的设计研发能力,结合国际先进的设计理念,自主设计研发生产电气柜壳体一次成型生产设备,配电柜自动成型设备,动力柜全自动生产线、威图柜立柱成型设备。

Our company is a school enterprise of Shandong Vocational College of Science and Technology, with registered capital of 10.15 million. It has strong design and research ability. Combining with international advanced design concepts, we independently design and develop the primary forming production equipment for electric cabinet shell, automatic forming equipment for distribution cabinet, automatic production line for power cabinet and column forming equipment for Weitu cabinet.

户外配电箱壳体一次成型设备,电气柜壳体一次成型机。

Outdoor distribution box shell primary forming equipment, electrical cabinet shell primary forming machine.

自动放料机—校平机—伺服送料机—冲孔部分—成型部分—定尺切断部分—自动折弯—收料台、机器人自动焊接,电气控制柜等部件组成。

Automatic feeder - leveler - servo feeder - punching part - forming part - fixed length cutting part - automatic bending - receiving table, robot automatic welding, electrical control cabinet and other components.

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

3、成型参数

3. Forming parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

潍坊炜桦冷弯机械制造有限公司(简称为“炜桦冷弯”)成立于2004年,位于世界著名的风筝之都--山东潍坊,是集设备制造、模具加工、技术开发于一体的综合性机械制造高科技民营企业,已成为建设部金属结构协会会员单位。2010年,公司与山东科技职业学院展开校企合作,委托学校为我公司培养了一大批技术熟练的产业工人,同时学校强大的科研队伍保障了我公司产品的高质量水准。2011年,公司为开拓国外市场,在上海成立上海三桑实业有限公司。2012年在江苏省苏州市(常熟)设立办事处,主要针对南方市场销售和售后服务。致力于高精度冷弯型钢及各种非标型材结构研究、设计、生产。是内外贸易一体的高度自动化机械制造型企业。

Weifang Weihua Cold Bending Machinery Manufacturing Co., Ltd. (hereinafter referred to as "Weifang Cold Bending") was established in 2004. It is located in Weifang, Shandong Province, the world-famous kite capital. It is a comprehensive high-tech private enterprise integrating equipment manufacturing, die processing and technology development. It has become a member unit of the Metal Structure Association of the Ministry of Construction. In 2010, the company cooperated with Shandong Vocational College of Science and Technology and entrusted the school to train a large number of skilled industrial workers for our company. Meanwhile, the school's strong scientific research team ensured the high quality of our products. In 2011, the company established Shanghai Sansang Industrial Co., Ltd. in order to open up foreign markets. In 2012, an office was set up in Suzhou, Jiangsu Province (Changshu), mainly for sales and after-sales services in the southern market. We are committed to the research, design and production of high precision cold-formed steel and various non-standard profiles. It is a highly automated machinery manufacturing enterprise integrating domestic and foreign trade.

户外配电箱壳体一次成型设备,电气柜壳体一次成型机。

Outdoor distribution box shell primary forming equipment, electrical cabinet shell primary forming machine.

自动放料机—校平机—伺服送料机—冲孔部分—成型部分—定尺切断部分—自动折弯—收料台、机器人自动焊接,电气控制柜等部件组成。

Automatic feeder - leveler - servo feeder - punching part - forming part - fixed length cutting part - automatic bending - receiving table, robot automatic welding, electrical control cabinet and other components.

一.主要技术参数

Main technical parameters

规格参数

Specification parameter

a. 适用材料: 冷轧卷板、镀锌卷板

Applicable materials: cold rolled and galvanized coils

b. 材料质量: 国产GB标准

B. Material Quality: Domestic GB Standard

c. 抗拉强度: δb≤780Mpa (Max.)

C. Tensile strength: delta B < 780 Mpa (Max.)

d. 屈服强度: δs≤510Mpa (Max.)

D. Yield strength: Delta s < 510 Mpa (Max.)

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

动力柜自动成型机参数:

设备占地空间: 25× 2× 2(长×宽×高)米

设备运行功率:25kw

生产速度:0-15m/min

成型道次:约20道

进料方向:从左至右

开卷机选用:5吨

冲压功率:5.5kw

校平机:4轴夹送9辊校平

我公司生产线的优点:

定制化设备:客户根据自己的生产要求,产品要求,厂房要求等进行定制,我公司依托自身强大的技术团队和学校资源(山东科技职业学院校办企业),满足客户的不同要求。

自动化:采用国内先进工艺,整合众多生产工艺,一人即可完成操作,节省人工及生产成本。

高速化:高度自动化、智能化,节省生产周期,提高生产效率。

安全:采用PLC控制器,内置多重安全防护,避免误伤。

耐用:设备多采用国际知名品牌,如日本三菱、施耐德、倍加福、欧姆龙等,降低故障率,节省生产时间成本,提高生产效率,降低维修成本。

部分数据:

生产线占地:22*2*1.8(长宽高)米

生产速度:每小时100个左右箱体。

公司介绍:

潍坊炜桦冷弯机械制造有限公司是专业的金属成型设备,自动化冷弯成型生产线的供应商。公司秉承诚信、团结、合作、共赢的理念,凭借良好的信誉、完美的质量、先进的科学技术,在几十年的过程中赢得了广泛的市场。公司拥有一批高素质的专业技术人员为设备的研发、只做、调试、安装及售后提供了保障。

m.weifangweihua.b2b168.com

The automatic production line of open-packed electric box shell and the automatic production line of middle-packed electric box can be produced quickly by one person. It not only saves the labor, but also improves the production efficiency, and at the same time improves the product quality.

我公司是山东科技职业学院校企,注册资金1015万,拥有强大的设计研发能力,结合国际先进的设计理念,自主设计研发生产电气柜壳体一次成型生产设备,配电柜自动成型设备,动力柜全自动生产线、威图柜立柱成型设备。

Our company is a school enterprise of Shandong Vocational College of Science and Technology, with registered capital of 10.15 million. It has strong design and research ability. Combining with international advanced design concepts, we independently design and develop the primary forming production equipment for electric cabinet shell, automatic forming equipment for distribution cabinet, automatic production line for power cabinet and column forming equipment for Weitu cabinet.

户外配电箱壳体一次成型设备,电气柜壳体一次成型机。

Outdoor distribution box shell primary forming equipment, electrical cabinet shell primary forming machine.

自动放料机—校平机—伺服送料机—冲孔部分—成型部分—定尺切断部分—自动折弯—收料台、机器人自动焊接,电气控制柜等部件组成。

Automatic feeder - leveler - servo feeder - punching part - forming part - fixed length cutting part - automatic bending - receiving table, robot automatic welding, electrical control cabinet and other components.

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

3、成型参数

3. Forming parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

潍坊炜桦冷弯机械制造有限公司(简称为“炜桦冷弯”)成立于2004年,位于世界著名的风筝之都--山东潍坊,是集设备制造、模具加工、技术开发于一体的综合性机械制造高科技民营企业,已成为建设部金属结构协会会员单位。2010年,公司与山东科技职业学院展开校企合作,委托学校为我公司培养了一大批技术熟练的产业工人,同时学校强大的科研队伍保障了我公司产品的高质量水准。2011年,公司为开拓国外市场,在上海成立上海三桑实业有限公司。2012年在江苏省苏州市(常熟)设立办事处,主要针对南方市场销售和售后服务。致力于高精度冷弯型钢及各种非标型材结构研究、设计、生产。是内外贸易一体的高度自动化机械制造型企业。

Weifang Weihua Cold Bending Machinery Manufacturing Co., Ltd. (hereinafter referred to as "Weifang Cold Bending") was established in 2004. It is located in Weifang, Shandong Province, the world-famous kite capital. It is a comprehensive high-tech private enterprise integrating equipment manufacturing, die processing and technology development. It has become a member unit of the Metal Structure Association of the Ministry of Construction. In 2010, the company cooperated with Shandong Vocational College of Science and Technology and entrusted the school to train a large number of skilled industrial workers for our company. Meanwhile, the school's strong scientific research team ensured the high quality of our products. In 2011, the company established Shanghai Sansang Industrial Co., Ltd. in order to open up foreign markets. In 2012, an office was set up in Suzhou, Jiangsu Province (Changshu), mainly for sales and after-sales services in the southern market. We are committed to the research, design and production of high precision cold-formed steel and various non-standard profiles. It is a highly automated machinery manufacturing enterprise integrating domestic and foreign trade.

户外配电箱壳体一次成型设备,电气柜壳体一次成型机。

Outdoor distribution box shell primary forming equipment, electrical cabinet shell primary forming machine.

自动放料机—校平机—伺服送料机—冲孔部分—成型部分—定尺切断部分—自动折弯—收料台、机器人自动焊接,电气控制柜等部件组成。

Automatic feeder - leveler - servo feeder - punching part - forming part - fixed length cutting part - automatic bending - receiving table, robot automatic welding, electrical control cabinet and other components.

一.主要技术参数

Main technical parameters

规格参数

Specification parameter

a. 适用材料: 冷轧卷板、镀锌卷板

Applicable materials: cold rolled and galvanized coils

b. 材料质量: 国产GB标准

B. Material Quality: Domestic GB Standard

c. 抗拉强度: δb≤780Mpa (Max.)

C. Tensile strength: delta B < 780 Mpa (Max.)

d. 屈服强度: δs≤510Mpa (Max.)

D. Yield strength: Delta s < 510 Mpa (Max.)

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

动力柜自动成型机参数:

设备占地空间: 25× 2× 2(长×宽×高)米

设备运行功率:25kw

生产速度:0-15m/min

成型道次:约20道

进料方向:从左至右

开卷机选用:5吨

冲压功率:5.5kw

校平机:4轴夹送9辊校平

我公司生产线的优点:

定制化设备:客户根据自己的生产要求,产品要求,厂房要求等进行定制,我公司依托自身强大的技术团队和学校资源(山东科技职业学院校办企业),满足客户的不同要求。

自动化:采用国内先进工艺,整合众多生产工艺,一人即可完成操作,节省人工及生产成本。

高速化:高度自动化、智能化,节省生产周期,提高生产效率。

安全:采用PLC控制器,内置多重安全防护,避免误伤。

耐用:设备多采用国际知名品牌,如日本三菱、施耐德、倍加福、欧姆龙等,降低故障率,节省生产时间成本,提高生产效率,降低维修成本。

部分数据:

生产线占地:22*2*1.8(长宽高)米

生产速度:每小时100个左右箱体。

公司介绍:

潍坊炜桦冷弯机械制造有限公司是专业的金属成型设备,自动化冷弯成型生产线的供应商。公司秉承诚信、团结、合作、共赢的理念,凭借良好的信誉、完美的质量、先进的科学技术,在几十年的过程中赢得了广泛的市场。公司拥有一批高素质的专业技术人员为设备的研发、只做、调试、安装及售后提供了保障。

m.weifangweihua.b2b168.com