沧州消防箱箱体生产线品牌

浏览次数:56次

- 产品规格:

- 发货地:山东省潍坊潍城区望留街道

关键词

沧州消防箱箱体生产线品牌

详细说明

本公司是一家以主营自动化冷弯成型设备,高精度异型材成型设备,高精度型钢生产设备,高精度带钢冷弯设备优秀企业。潍坊炜桦冷弯机械制造有限公司(简称为“炜桦冷弯”)

配电箱箱体冷弯成型设备的核心部件是轧辊模具,潍坊炜桦冷弯机械有限公司在轧辊制造方面,先由技术部进行专业的设计,经过严格审核后流转到生产部加工,我们采用的材料材质都是非常优质的,为保障轧辊的 使用寿命,我们有着严格有序的加工流程,虽然繁琐一些,但是能够让客户用着放心舒心,一切也是值得的。具体的轧辊加工流程这里不便详细说明,您有兴趣的话可以找我们了解一下。

The core component of cold bending forming equipment for distribution box body is roll mould. Weifang Weihua Cold Bending Machinery Co., Ltd. specializes in roll manufacturing. After strict examination, it is transferred to the production department for processing. The materials we adopt are of very high quality. In order to ensure the service life of rolls, we have a strict and orderly processing process, although complicated. It's trivial, but it's worth it to make customers feel at ease with it. Specific roll processing process here is not convenient to elaborate, if you are interested, you can find out about us.

配电箱自动冷弯成型生产线为定制化设备,可根据客户的不同需求,集成生产所需的众多工艺,如自动换料机、切割和冲压系统,以及复杂的焊接、铆接、折弯、搬运和包装等系统。这些都将为提高生产能力带来巨大的附加值。其生产的冷弯成型生产线设备:轧制材料的材质包括冷轧钢带、热轧钢带、酸洗板(钢带)、彩钢板(钢带)、镀锌钢带和不锈钢带等;高精度成型机专业制造能处理0.2mm—12mm厚金属板材;生产出来的型材尺寸精度可以控制在0.05毫米以内,这在国内具有行业领先地位。

The automatic cold bending production line for distribution boxes is customized equipment. It can integrate many processes required for production according to different needs of customers, such as automatic feeder, cutting and stamping system, and complex welding, riveting, bending, handling and packaging systems. All of these will bring huge added value to the improvement of production capacity. The cold bending production line equipment: the material of rolling material includes cold rolled steel strip, hot rolled steel strip, pickling plate (steel strip), coloured steel strip (steel strip), galvanized steel strip and stainless steel strip, etc. The high precision forming machine specializes in manufacturing thick metal sheet which can handle 0.2mm-12mm; the dimension precision of the produced profile can be controlled within 0.05mm, which is the leading industry in China. Position.

钢带厚度:1.0~2.0 mm

Strip thickness: 1.0-2.0 mm

钢带宽度:≤500mm,

Width of steel band: <500 mm,

轧辊材质:GCr15 淬火HRC58°-62°

Roll Material: GCr15 Quenched HRC58 Degree-62 Degree

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

总电机功率:27kw

Total motor power: 27 kw

液压系统功率:3kw

Hydraulic system power: 3kw

承重钢带:3吨

Load-bearing steel strip: 3 tons

主要轧辊数量:18

Number of main rolls: 18

切断尺寸公差:≤ ±0.5mm(长≤3000mm)

Cut-off dimension tolerance: <0.5mm (length <3000mm)

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

气源:0.5m³/Min;压力为0.7MPa

Gas source: 0.5m_/Min; pressure 0.7MPa

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times.

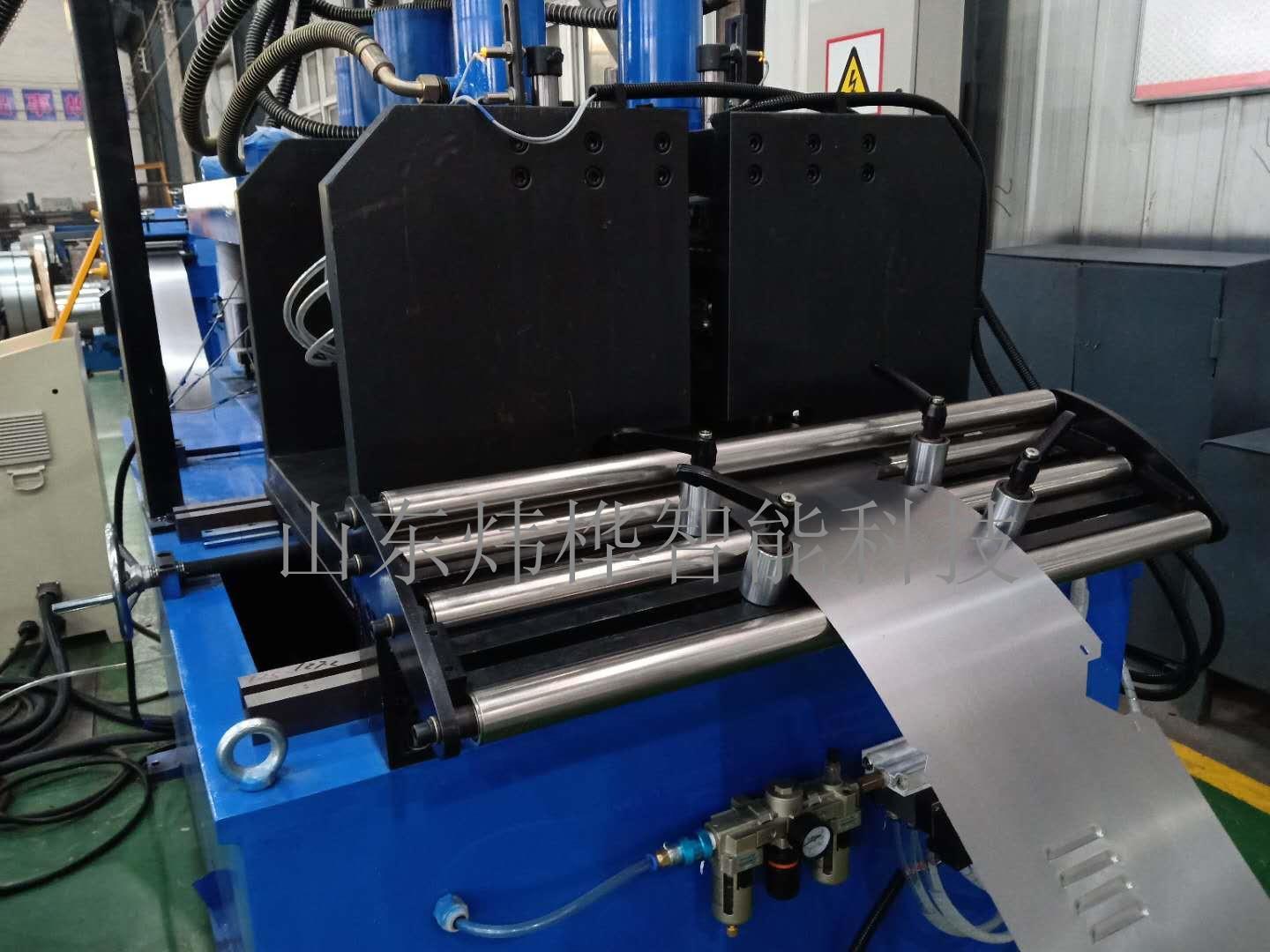

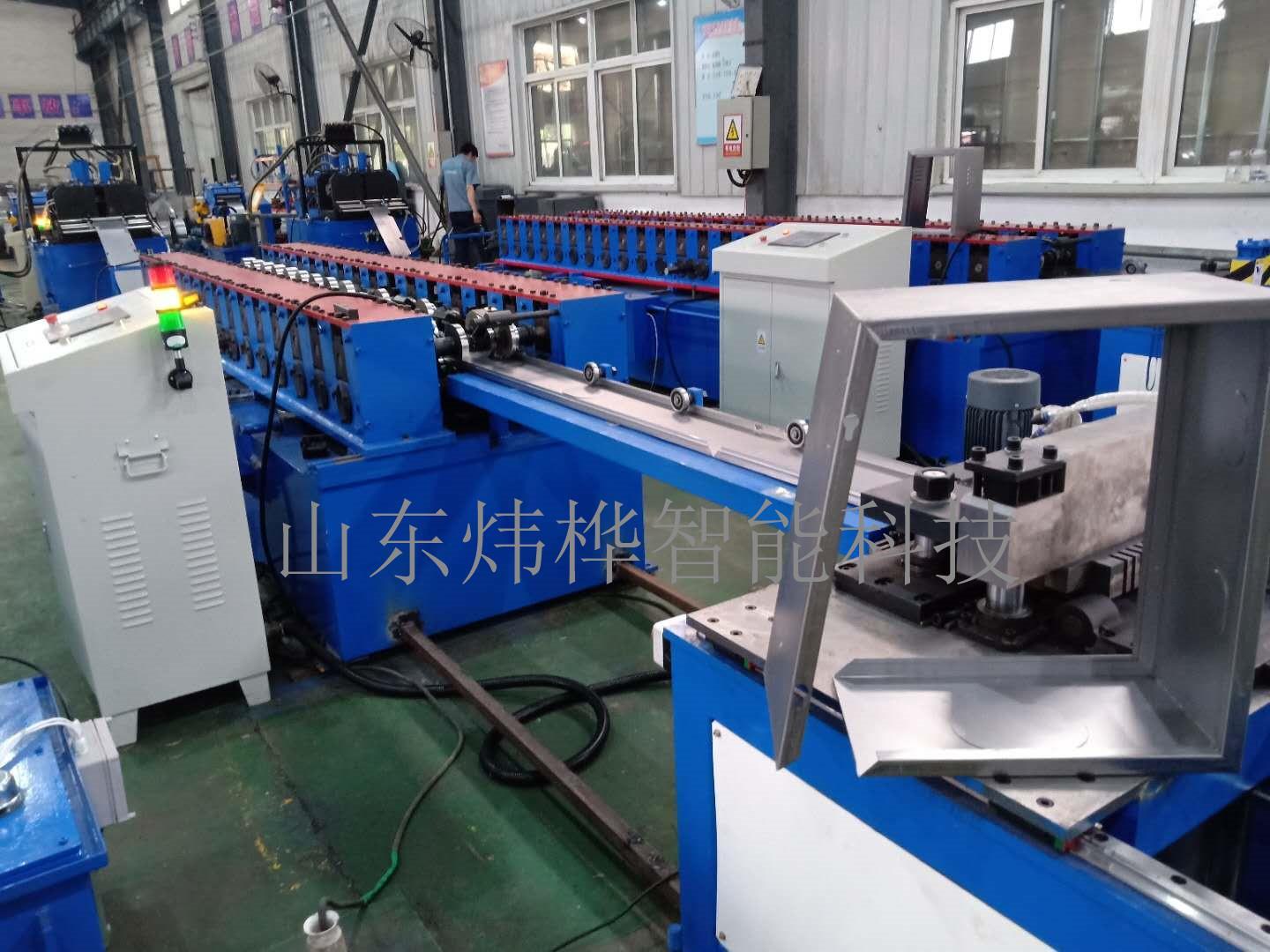

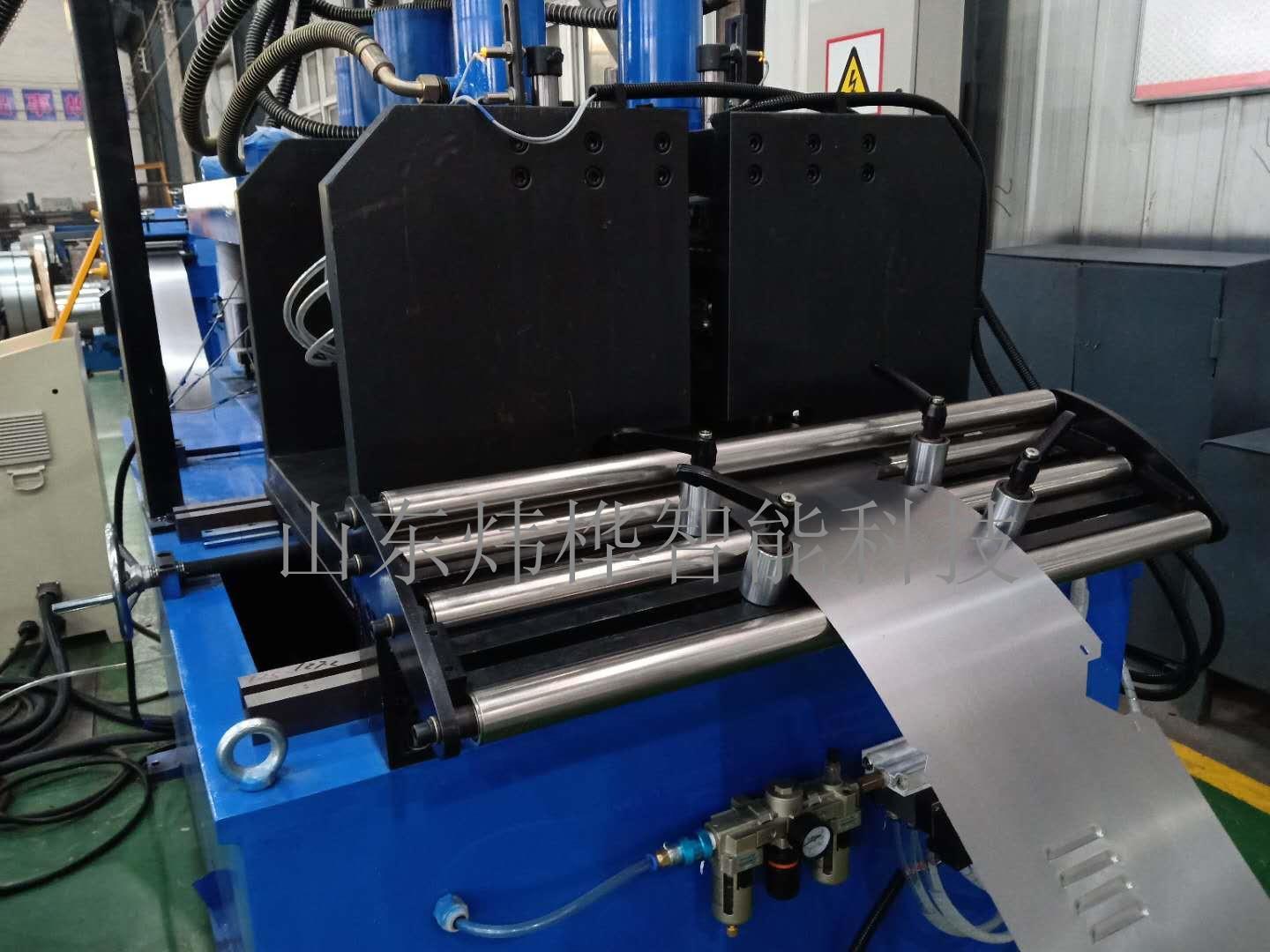

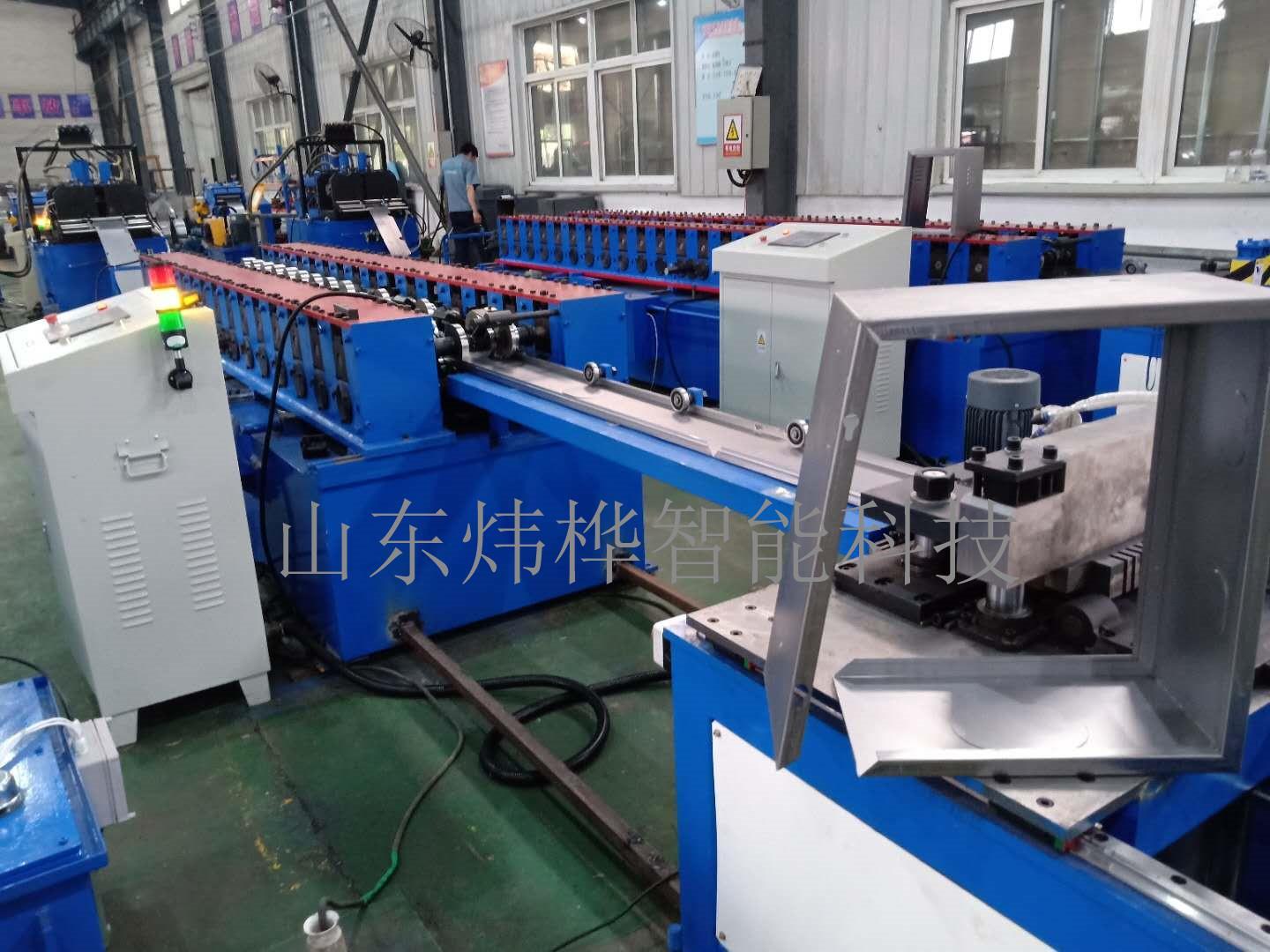

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

自动化生产线优点:

Advantages of automatic production line:

1、高度的自动化程序,减少人工操作;

1. Highly automated procedures to reduce manual operation;

2、工作效率高,提高企业产能;

2. High working efficiency, improve enterprise productivity;

3、整个工艺的生产流程稳定,提高产品的品质和一致性;

3. The production process of the whole process is stable and the quality and consistency of the products are improved.

4、大批量生产,降低了企业生产成本。

4. Mass production reduces the production cost of enterprises.

配电箱生产线工艺流程:

Distribution box production line process:

带钢上料→钢卷放料→材料校平→高精度伺服送料→多工位组合式伺服冲孔→高精度冷弯成型→切断→折框→收料→电气控制系统

Strip feeding steel coil discharge material leveling high precision servo feeding multi-station combined servo punching high precision cold bending forming cutting folding frame feeding electrical control system

自动放料机、校平\送料部分、连续冲孔部分、成型部分、定尺切断部分、收料台、电器控制柜等部件组成。

Automatic feeder, leveling feeding part, continuous punching part, forming part, fixed length cut-off part, feeding table, electrical control cabinet and other components.

配电箱成型设备简要参数

Brief Parameters of Shaping Equipment for Distribution Box

e、 底板厚度:20mm

E. Floor thickness: 20mm

4、成型能力

4. Forming ability

a. 带卷外径: Φ1250mm(Max.)

A. Outer diameter of tape coil: 1250mm (Max.)

b. 材料成型厚度:0.4-1.0mm

B. Material forming thickness: 0.4-1.0mm

c. 产品宽度100mm-400mm可调

C. The width of the product is adjustable from 100mm to 400mm.

5、成型机组速度参数

5. Speed parameters of forming unit

a. 线速度 0-13m/min

A. Linear velocity 0-13m/min

b. 加速时间 <30秒

B. Acceleration time less than 30 seconds

6、成型精度

6. Forming accuracy

a. 剪切长度公差:≤±0.3mm/m

A. Shear length tolerance: <0.3m m/m

b. 宽度公差: ≤±0.3mm

B. Width tolerance: <0.3mm

c. 镰 刀 弯: ≤2mm/m

C. Sickle bending: <2m m/m

d. 毛刺: ≤0.1mm(新刀刃在合理间隙剪切普碳钢板)

D. Burr: <0.1mm (new blade shearing plain carbon steel plate in reasonable clearance)

e. 高度公差:≤±0.3mm

E. Height tolerance: <0.3mm

? 以上公差以平坦无边波之一级钢卷为前提。

The above tolerance is based on the first grade coil with flat edgeless wave.

? 表面品质:加工后成品表面不增加任何加工缺陷。

Surface quality: No processing defects are added to the surface of finished products after processing.

设备结构及系统配置:

Equipment structure and system configuration:

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用25mm钢板,支承部分均采用优质台湾轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame adopts integral fixed archway, the side plate adopts 25mm steel plate, the supporting part adopts high-quality Taiwanese bearings, the feeding part adopts roller type, the discharging part adopts torsion up and down adjustment, the main machine has good steel and stable structure.

B:滚压模具(轧辘):16组辊轮成型,均采用优质Gr12模具钢,HRC达58~60o均采用精密数控机床加工,精度为6~7级,表面粗糙度达0.8 以上,成形尺寸精确,成形工件表面无划伤。

B: Rolling dies (rollers): 16 groups of rollers are formed with high quality Gr12 die steel, HRC up to 58~60o are processed with precision CNC machine tools, accuracy is 6~7 grades, surface roughness is more than 0.8, forming dimension is accurate, no scratches on the surface of the formed workpiece.

C:传动部分:是生产线成形动力的输送部分,其动力由主电机到减速箱,再由减速箱通过齿轮传送到主动轮上,主动轮通过过度齿轮传动,使得上下轧辘同步转动。

C: Driving part: It is the conveying part of the forming power of the production line. Its power is transferred from the main motor to the reducer, and then from the reducer to the driving wheel through gears. The driving wheel is driven by excessive gears, so that the upper and lower rollers rotate synchronously.

3.定长折弯部分:由定长装置及折弯机构组成。定长装置是通过激光探头结合编码器定长,当板料走到定尺长度时,通过PLC控制折弯产品。

3. Fixed length bending part: It consists of fixed length device and bending mechanism. The fixed length device is fixed by laser probe combined with encoder. When the sheet reaches the fixed length, the bending product is controlled by PLC.

4.托料架:此装置在成型机的后面,根据产品长度的不同合理排布。

4. Bracket: The device is arranged reasonably in the back of the forming machine according to the length of the product.

5.电控系统:整条生产线采用集中控制,元件采用进口及国产上等优质产品,或由客户指定,标准件元件采用台湾品牌。设备电控元件的安装符合国家规定,线号清晰。

5. Electronic control system: The whole production line adopts centralized control. The components are imported and domestic high-quality products, or designated by customers. The standard components are made of Taiwan brand. The installation of the electronic control components of the equipment conforms to the national regulations, and the line number is clear.

操作系统:触摸屏

Operating System: Touch Screen

控制方式:PLC

Control mode: PLC

传动模式:齿轮箱

Drive mode: gearbox

材料规格:Q235

Material Specification: Q235

生产速度:0-15m

Production speed: 0-15m

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

钢带厚度:0-6mm

Strip thickness: 0-6mm

m.weifangweihua.b2b168.com

配电箱箱体冷弯成型设备的核心部件是轧辊模具,潍坊炜桦冷弯机械有限公司在轧辊制造方面,先由技术部进行专业的设计,经过严格审核后流转到生产部加工,我们采用的材料材质都是非常优质的,为保障轧辊的 使用寿命,我们有着严格有序的加工流程,虽然繁琐一些,但是能够让客户用着放心舒心,一切也是值得的。具体的轧辊加工流程这里不便详细说明,您有兴趣的话可以找我们了解一下。

The core component of cold bending forming equipment for distribution box body is roll mould. Weifang Weihua Cold Bending Machinery Co., Ltd. specializes in roll manufacturing. After strict examination, it is transferred to the production department for processing. The materials we adopt are of very high quality. In order to ensure the service life of rolls, we have a strict and orderly processing process, although complicated. It's trivial, but it's worth it to make customers feel at ease with it. Specific roll processing process here is not convenient to elaborate, if you are interested, you can find out about us.

配电箱自动冷弯成型生产线为定制化设备,可根据客户的不同需求,集成生产所需的众多工艺,如自动换料机、切割和冲压系统,以及复杂的焊接、铆接、折弯、搬运和包装等系统。这些都将为提高生产能力带来巨大的附加值。其生产的冷弯成型生产线设备:轧制材料的材质包括冷轧钢带、热轧钢带、酸洗板(钢带)、彩钢板(钢带)、镀锌钢带和不锈钢带等;高精度成型机专业制造能处理0.2mm—12mm厚金属板材;生产出来的型材尺寸精度可以控制在0.05毫米以内,这在国内具有行业领先地位。

The automatic cold bending production line for distribution boxes is customized equipment. It can integrate many processes required for production according to different needs of customers, such as automatic feeder, cutting and stamping system, and complex welding, riveting, bending, handling and packaging systems. All of these will bring huge added value to the improvement of production capacity. The cold bending production line equipment: the material of rolling material includes cold rolled steel strip, hot rolled steel strip, pickling plate (steel strip), coloured steel strip (steel strip), galvanized steel strip and stainless steel strip, etc. The high precision forming machine specializes in manufacturing thick metal sheet which can handle 0.2mm-12mm; the dimension precision of the produced profile can be controlled within 0.05mm, which is the leading industry in China. Position.

钢带厚度:1.0~2.0 mm

Strip thickness: 1.0-2.0 mm

钢带宽度:≤500mm,

Width of steel band: <500 mm,

轧辊材质:GCr15 淬火HRC58°-62°

Roll Material: GCr15 Quenched HRC58 Degree-62 Degree

液压油型号:46#液压油

Hydraulic Oil Type: 46 # Hydraulic Oil

齿轮油型号:18#齿轮油

Gear Oil Type: 18 # Gear Oil

总电机功率:27kw

Total motor power: 27 kw

液压系统功率:3kw

Hydraulic system power: 3kw

承重钢带:3吨

Load-bearing steel strip: 3 tons

主要轧辊数量:18

Number of main rolls: 18

切断尺寸公差:≤ ±0.5mm(长≤3000mm)

Cut-off dimension tolerance: <0.5mm (length <3000mm)

切断模具材质: Cr12MoV

Cutting Die Material: Cr12MoV

气源:0.5m³/Min;压力为0.7MPa

Gas source: 0.5m_/Min; pressure 0.7MPa

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times.

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

自动化生产线优点:

Advantages of automatic production line:

1、高度的自动化程序,减少人工操作;

1. Highly automated procedures to reduce manual operation;

2、工作效率高,提高企业产能;

2. High working efficiency, improve enterprise productivity;

3、整个工艺的生产流程稳定,提高产品的品质和一致性;

3. The production process of the whole process is stable and the quality and consistency of the products are improved.

4、大批量生产,降低了企业生产成本。

4. Mass production reduces the production cost of enterprises.

配电箱生产线工艺流程:

Distribution box production line process:

带钢上料→钢卷放料→材料校平→高精度伺服送料→多工位组合式伺服冲孔→高精度冷弯成型→切断→折框→收料→电气控制系统

Strip feeding steel coil discharge material leveling high precision servo feeding multi-station combined servo punching high precision cold bending forming cutting folding frame feeding electrical control system

自动放料机、校平\送料部分、连续冲孔部分、成型部分、定尺切断部分、收料台、电器控制柜等部件组成。

Automatic feeder, leveling feeding part, continuous punching part, forming part, fixed length cut-off part, feeding table, electrical control cabinet and other components.

配电箱成型设备简要参数

Brief Parameters of Shaping Equipment for Distribution Box

e、 底板厚度:20mm

E. Floor thickness: 20mm

4、成型能力

4. Forming ability

a. 带卷外径: Φ1250mm(Max.)

A. Outer diameter of tape coil: 1250mm (Max.)

b. 材料成型厚度:0.4-1.0mm

B. Material forming thickness: 0.4-1.0mm

c. 产品宽度100mm-400mm可调

C. The width of the product is adjustable from 100mm to 400mm.

5、成型机组速度参数

5. Speed parameters of forming unit

a. 线速度 0-13m/min

A. Linear velocity 0-13m/min

b. 加速时间 <30秒

B. Acceleration time less than 30 seconds

6、成型精度

6. Forming accuracy

a. 剪切长度公差:≤±0.3mm/m

A. Shear length tolerance: <0.3m m/m

b. 宽度公差: ≤±0.3mm

B. Width tolerance: <0.3mm

c. 镰 刀 弯: ≤2mm/m

C. Sickle bending: <2m m/m

d. 毛刺: ≤0.1mm(新刀刃在合理间隙剪切普碳钢板)

D. Burr: <0.1mm (new blade shearing plain carbon steel plate in reasonable clearance)

e. 高度公差:≤±0.3mm

E. Height tolerance: <0.3mm

? 以上公差以平坦无边波之一级钢卷为前提。

The above tolerance is based on the first grade coil with flat edgeless wave.

? 表面品质:加工后成品表面不增加任何加工缺陷。

Surface quality: No processing defects are added to the surface of finished products after processing.

设备结构及系统配置:

Equipment structure and system configuration:

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用25mm钢板,支承部分均采用优质台湾轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame adopts integral fixed archway, the side plate adopts 25mm steel plate, the supporting part adopts high-quality Taiwanese bearings, the feeding part adopts roller type, the discharging part adopts torsion up and down adjustment, the main machine has good steel and stable structure.

B:滚压模具(轧辘):16组辊轮成型,均采用优质Gr12模具钢,HRC达58~60o均采用精密数控机床加工,精度为6~7级,表面粗糙度达0.8 以上,成形尺寸精确,成形工件表面无划伤。

B: Rolling dies (rollers): 16 groups of rollers are formed with high quality Gr12 die steel, HRC up to 58~60o are processed with precision CNC machine tools, accuracy is 6~7 grades, surface roughness is more than 0.8, forming dimension is accurate, no scratches on the surface of the formed workpiece.

C:传动部分:是生产线成形动力的输送部分,其动力由主电机到减速箱,再由减速箱通过齿轮传送到主动轮上,主动轮通过过度齿轮传动,使得上下轧辘同步转动。

C: Driving part: It is the conveying part of the forming power of the production line. Its power is transferred from the main motor to the reducer, and then from the reducer to the driving wheel through gears. The driving wheel is driven by excessive gears, so that the upper and lower rollers rotate synchronously.

3.定长折弯部分:由定长装置及折弯机构组成。定长装置是通过激光探头结合编码器定长,当板料走到定尺长度时,通过PLC控制折弯产品。

3. Fixed length bending part: It consists of fixed length device and bending mechanism. The fixed length device is fixed by laser probe combined with encoder. When the sheet reaches the fixed length, the bending product is controlled by PLC.

4.托料架:此装置在成型机的后面,根据产品长度的不同合理排布。

4. Bracket: The device is arranged reasonably in the back of the forming machine according to the length of the product.

5.电控系统:整条生产线采用集中控制,元件采用进口及国产上等优质产品,或由客户指定,标准件元件采用台湾品牌。设备电控元件的安装符合国家规定,线号清晰。

5. Electronic control system: The whole production line adopts centralized control. The components are imported and domestic high-quality products, or designated by customers. The standard components are made of Taiwan brand. The installation of the electronic control components of the equipment conforms to the national regulations, and the line number is clear.

操作系统:触摸屏

Operating System: Touch Screen

控制方式:PLC

Control mode: PLC

传动模式:齿轮箱

Drive mode: gearbox

材料规格:Q235

Material Specification: Q235

生产速度:0-15m

Production speed: 0-15m

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

钢带厚度:0-6mm

Strip thickness: 0-6mm

m.weifangweihua.b2b168.com