成都迷你消防箱箱体生产线

浏览次数:131次

- 产品规格:

- 发货地:山东省潍坊潍城区望留街道

关键词

成都迷你消防箱箱体生产线

详细说明

优质消防箱成型设备基本参数:

材料材质:Q235 、不锈钢等

带卷厚度:0.5-1.5 mm

生产速度:大约100个四边箱体/H

总电机功率:20kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机

开卷机称重:5吨

设备结构及系统配置:

Equipment structure and system configuration:

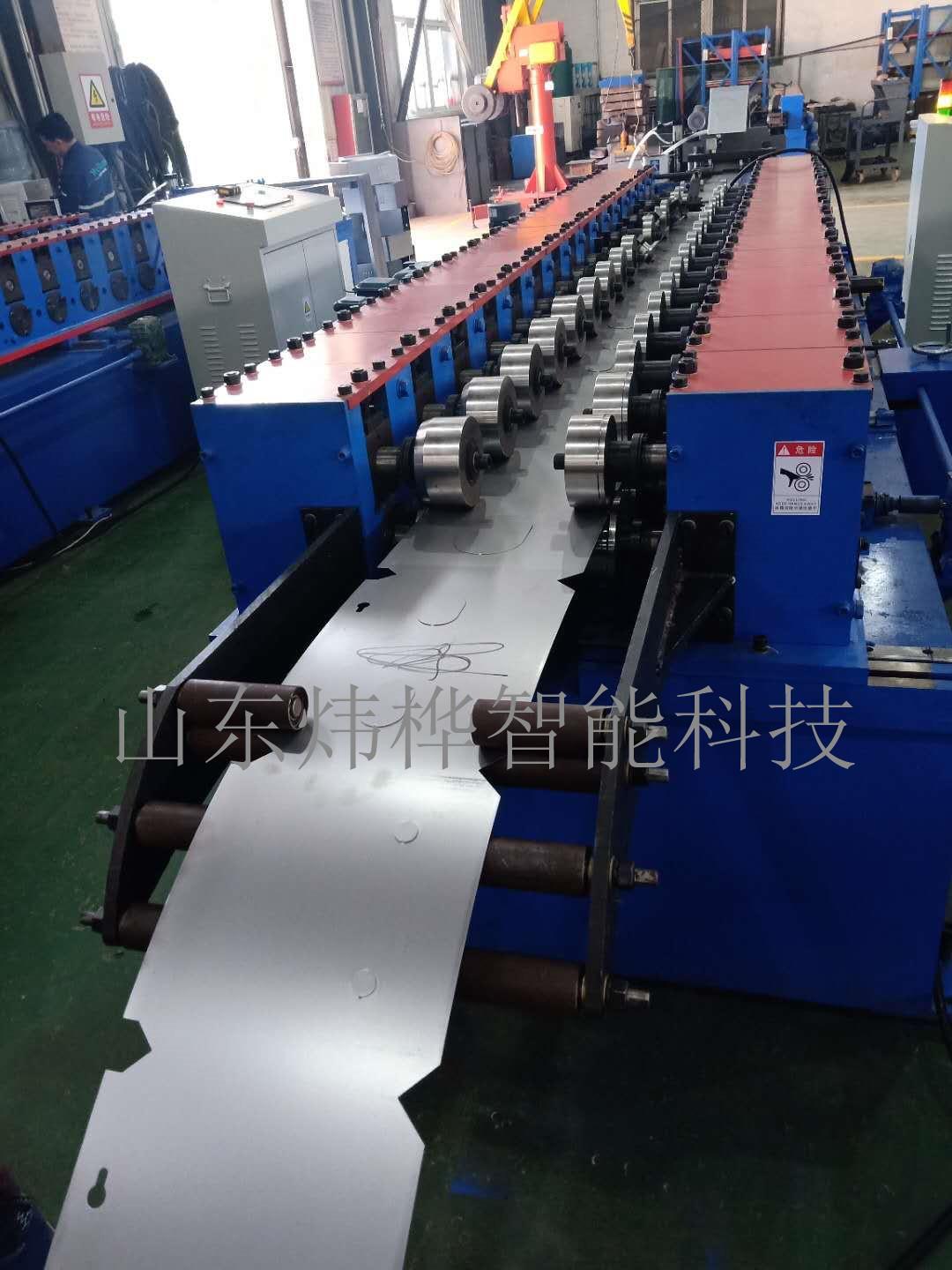

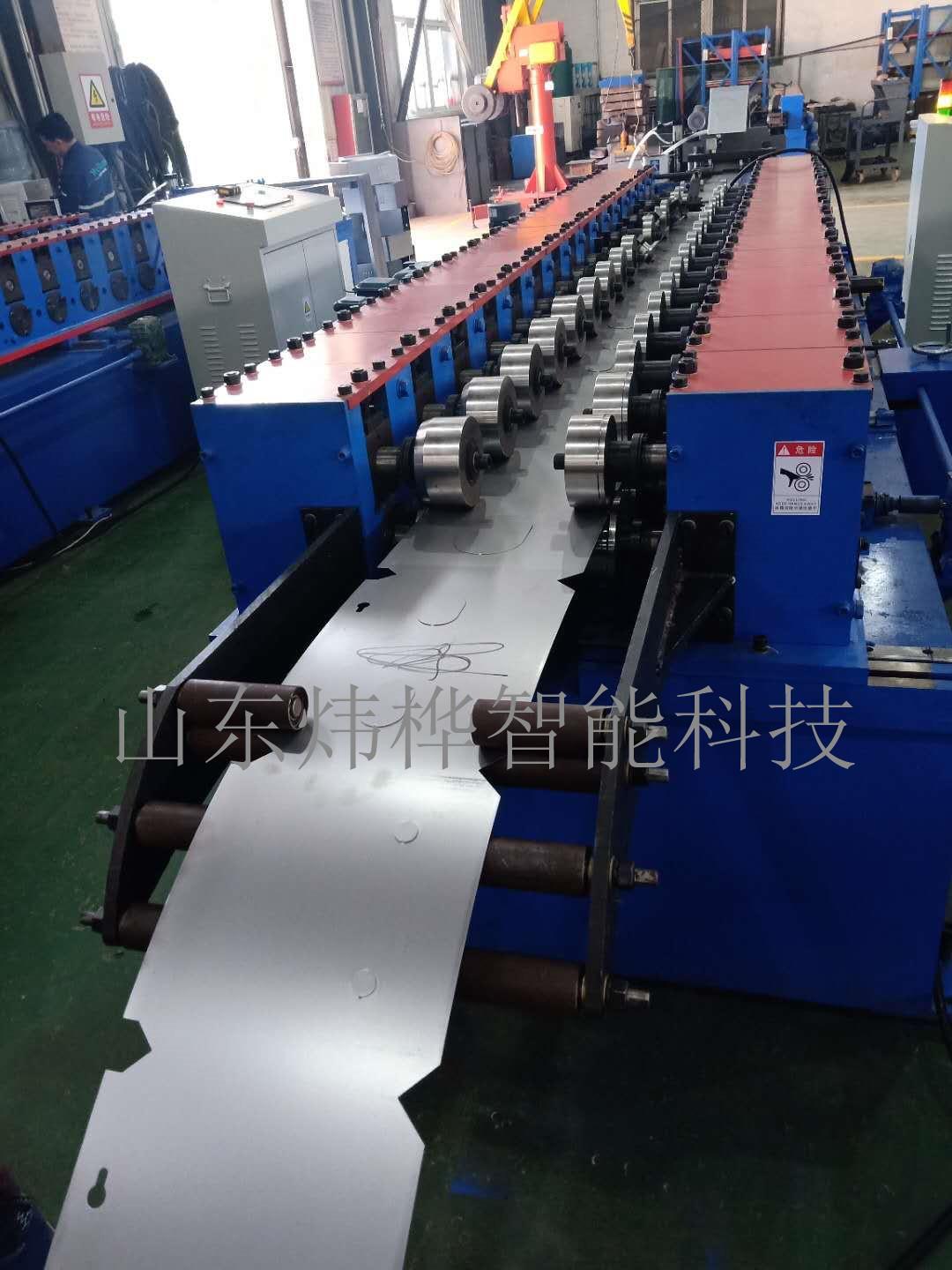

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用25mm钢板,支承部分均采用优质台湾轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame adopts integral fixed archway, the side plate adopts 25mm steel plate, the supporting part adopts high-quality Taiwanese bearings, the feeding part adopts roller type, the discharging part adopts torsion up and down adjustment, the main machine has good steel and stable structure.

B:滚压模具(轧辘):16组辊轮成型,均采用优质Gr12模具钢,HRC达58~60o均采用精密数控机床加工,精度为6~7级,表面粗糙度达0.8 以上,成形尺寸精确,成形工件表面无划伤。

B: Rolling dies (rollers): 16 groups of rollers are formed with high quality Gr12 die steel, HRC up to 58~60o are processed with precision CNC machine tools, accuracy is 6~7 grades, surface roughness is more than 0.8, forming dimension is accurate, no scratches on the surface of the formed workpiece.

C:传动部分:是生产线成形动力的输送部分,其动力由主电机到减速箱,再由减速箱通过齿轮传送到主动轮上,主动轮通过过度齿轮传动,使得上下轧辘同步转动。

C: Driving part: It is the conveying part of the forming power of the production line. Its power is transferred from the main motor to the reducer, and then from the reducer to the driving wheel through gears. The driving wheel is driven by excessive gears, so that the upper and lower rollers rotate synchronously.

3.定长折弯部分:由定长装置及折弯机构组成。定长装置是通过激光探头结合编码器定长,当板料走到定尺长度时,通过PLC控制折弯产品。

3. Fixed length bending part: It consists of fixed length device and bending mechanism. The fixed length device is fixed by laser probe combined with encoder. When the sheet reaches the fixed length, the bending product is controlled by PLC.

4.托料架:此装置在成型机的后面,根据产品长度的不同合理排布。

4. Bracket: The device is arranged reasonably in the back of the forming machine according to the length of the product.

5.电控系统:整条生产线采用集中控制,元件采用进口及国产上等优质产品,或由客户指定,标准件元件采用台湾品牌。设备电控元件的安装符合国家规定,线号清晰。

5. Electronic control system: The whole production line adopts centralized control. The components are imported and domestic high-quality products, or designated by customers. The standard components are made of Taiwan brand. The installation of the electronic control components of the equipment conforms to the national regulations, and the line number is clear.

操作系统:触摸屏

Operating System: Touch Screen

控制方式:PLC

Control mode: PLC

传动模式:齿轮箱

Drive mode: gearbox

材料规格:Q235

Material Specification: Q235

生产速度:0-15m

Production speed: 0-15m

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

钢带厚度:0-6mm

Strip thickness: 0-6mm

新型箱体产品特点:

Features of new box products:

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!日生产箱体1000只,在人员和场地减少的情况下,实现实际生产效率增加数倍;伺服控制和高精度冷弯成型等多项国家技术,确保了箱体的钣金制造精度,实现箱体机械强度更高。

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times. The daily production of 1000 boxes, in the case of reduced personnel and site, to achieve a multiplier of the actual production efficiency; servo control and high-precision cold bending forming and other national technologies, to ensure the accuracy of the box sheet metal manufacturing, to achieve higher mechanical strength of the box.

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

.主要技术参数规格参数

Main technical parameters, specifications and parameters

a. 适用材料: 冷轧卷板、镀锌卷板

Applicable materials: cold rolled and galvanized coils

b. 材料质量: 国产GB标准

B. Material Quality: Domestic GB Standard

c. 抗拉强度: δb≤780Mpa (Max.)

C. Tensile strength: delta B < 780 Mpa (Max.)

d. 屈服强度: δs≤510Mpa (Max.)

D. Yield strength: Delta s < 510 Mpa (Max.)

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

3、成型参数

3. Forming parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

潍坊炜桦冷弯机械制造有限公司面向潍坊地区用户推荐消防箱全自动生产线,消防箱自动生产设备,消防箱箱体生产线,新型消防箱生产线。

m.weifangweihua.b2b168.com

材料材质:Q235 、不锈钢等

带卷厚度:0.5-1.5 mm

生产速度:大约100个四边箱体/H

总电机功率:20kw

液压站功率:5.5kw

切断方式:液压切断

电气控制:PLC

驱动电机:变频电机

开卷机称重:5吨

设备结构及系统配置:

Equipment structure and system configuration:

概述:该生产线主要由放料机、调平机、冲孔切断机、输送台、成型主机、液压折边机、成品托料装置、液压系统、电气控制部分及安全防护部分组成。

Overview: The production line is mainly composed of feeder, leveler, punch cutter, conveyor, forming machine, hydraulic folding machine, finished product supporting device, hydraulic system, electrical control part and safety protection part.

成型主机:此生产线的主机机座采用100*100*3MM方钢焊接,机架采用整体式固定牌坊,侧板采用25mm钢板,支承部分均采用优质台湾轴承,进料采用滚轮式,出料采用扭动上下调节,主机钢性好,且结构稳定。

Forming machine: The main frame of this production line is welded with 100*100*3MM square steel, the frame adopts integral fixed archway, the side plate adopts 25mm steel plate, the supporting part adopts high-quality Taiwanese bearings, the feeding part adopts roller type, the discharging part adopts torsion up and down adjustment, the main machine has good steel and stable structure.

B:滚压模具(轧辘):16组辊轮成型,均采用优质Gr12模具钢,HRC达58~60o均采用精密数控机床加工,精度为6~7级,表面粗糙度达0.8 以上,成形尺寸精确,成形工件表面无划伤。

B: Rolling dies (rollers): 16 groups of rollers are formed with high quality Gr12 die steel, HRC up to 58~60o are processed with precision CNC machine tools, accuracy is 6~7 grades, surface roughness is more than 0.8, forming dimension is accurate, no scratches on the surface of the formed workpiece.

C:传动部分:是生产线成形动力的输送部分,其动力由主电机到减速箱,再由减速箱通过齿轮传送到主动轮上,主动轮通过过度齿轮传动,使得上下轧辘同步转动。

C: Driving part: It is the conveying part of the forming power of the production line. Its power is transferred from the main motor to the reducer, and then from the reducer to the driving wheel through gears. The driving wheel is driven by excessive gears, so that the upper and lower rollers rotate synchronously.

3.定长折弯部分:由定长装置及折弯机构组成。定长装置是通过激光探头结合编码器定长,当板料走到定尺长度时,通过PLC控制折弯产品。

3. Fixed length bending part: It consists of fixed length device and bending mechanism. The fixed length device is fixed by laser probe combined with encoder. When the sheet reaches the fixed length, the bending product is controlled by PLC.

4.托料架:此装置在成型机的后面,根据产品长度的不同合理排布。

4. Bracket: The device is arranged reasonably in the back of the forming machine according to the length of the product.

5.电控系统:整条生产线采用集中控制,元件采用进口及国产上等优质产品,或由客户指定,标准件元件采用台湾品牌。设备电控元件的安装符合国家规定,线号清晰。

5. Electronic control system: The whole production line adopts centralized control. The components are imported and domestic high-quality products, or designated by customers. The standard components are made of Taiwan brand. The installation of the electronic control components of the equipment conforms to the national regulations, and the line number is clear.

操作系统:触摸屏

Operating System: Touch Screen

控制方式:PLC

Control mode: PLC

传动模式:齿轮箱

Drive mode: gearbox

材料规格:Q235

Material Specification: Q235

生产速度:0-15m

Production speed: 0-15m

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

驱动电机:变频电机驱动

Driving motor: variable frequency motor drive

钢带厚度:0-6mm

Strip thickness: 0-6mm

新型箱体产品特点:

Features of new box products:

我公司研发的配电箱加工生产线为配电箱一次成型设备。该设备打破了传统生产方式,对多个工艺步骤进行了优化改进,使配电箱钣金加工的综合生产效率提高3倍以上,部分环节工序可提高效率10倍以上!日生产箱体1000只,在人员和场地减少的情况下,实现实际生产效率增加数倍;伺服控制和高精度冷弯成型等多项国家技术,确保了箱体的钣金制造精度,实现箱体机械强度更高。

The distribution box processing line developed by our company is the primary forming equipment of the distribution box. The equipment breaks the traditional production mode, optimizes and improves several process steps, and improves the overall production efficiency of sheet metal processing of distribution box by more than three times, and some process steps can improve efficiency by more than 10 times. The daily production of 1000 boxes, in the case of reduced personnel and site, to achieve a multiplier of the actual production efficiency; servo control and high-precision cold bending forming and other national technologies, to ensure the accuracy of the box sheet metal manufacturing, to achieve higher mechanical strength of the box.

该机组设备占地约50平方米,设备组成主要包括:放料装置、校平装置、自动送料装置、连续冲孔装置、高精度冷弯成型主机、定尺切断装置、自动折框装置、电气控制系统等部件组成;主要功能:自动去角、伺服自动冲孔、自动下料、自动成型、自动折框等。

The unit covers an area of about 50 square meters, and its equipment composition mainly includes: discharging device, leveling device, automatic feeding device, continuous punching device, high precision cold bending forming machine, fixed length cutting device, automatic folding frame device, electrical control system and other components; its main functions are automatic angle removal, Servo Automatic punching, automatic blanking, automatic forming, automatic folding frame, etc.

.主要技术参数规格参数

Main technical parameters, specifications and parameters

a. 适用材料: 冷轧卷板、镀锌卷板

Applicable materials: cold rolled and galvanized coils

b. 材料质量: 国产GB标准

B. Material Quality: Domestic GB Standard

c. 抗拉强度: δb≤780Mpa (Max.)

C. Tensile strength: delta B < 780 Mpa (Max.)

d. 屈服强度: δs≤510Mpa (Max.)

D. Yield strength: Delta s < 510 Mpa (Max.)

e. 材料厚度: 0.4-1.0mm

E. Material thickness: 0.4-1.0mm

f. 材料宽度: 150-500mm (Max.)

F. Material width: 150-500 mm (Max.)

g. 钢卷内径: Φ360mm-Φ510mm

G. Coil inner diameter: 360mm-510mm

h. 钢卷外径: Φ1250(Max.)

H. Outer diameter of coil: 1250 (Max.)

i. 钢卷重量: 5 t(Max.)

I. Coil weight: 5 t (Max.)

3、成型参数

3. Forming parameters

a、 成型组数:16组辊轮成型

A. Forming group: 16 sets of rollers forming

b、 主轴规格:?48mm 45#钢材料调质处理

B. Spindle specification:? 48mm 45# steel material tempering treatment

c、 辊轮材质:Gr12模具钢热处理

C. Roller Material: Heat Treatment of Gr12 Die Steel

d、 整体式牌坊:由25mm钢板精加工而成,孔距误差小于0.1mm

D. Integral archway: made of 25 mm steel plate, with hole spacing error less than 0.1 mm

潍坊炜桦冷弯机械制造有限公司面向潍坊地区用户推荐消防箱全自动生产线,消防箱自动生产设备,消防箱箱体生产线,新型消防箱生产线。

m.weifangweihua.b2b168.com